Since 1952 Tallman has been Setting the Standard for Linemen

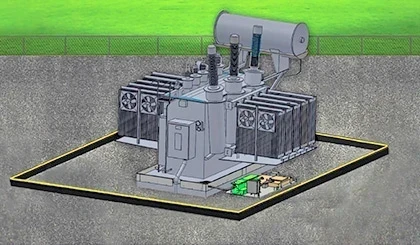

At Tallman Equipment, we are an employee-owned company that provides tools, equipment, and services for the construction and maintenance of Electrical Transmission and distribution infrastructure. Whether it’s a large, multi-state construction project, managing a storm, or providing power to...