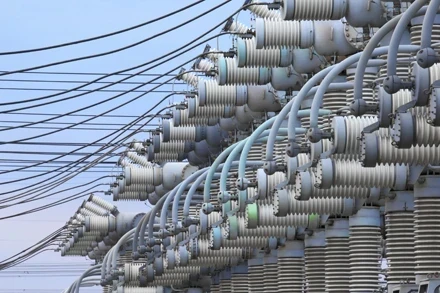

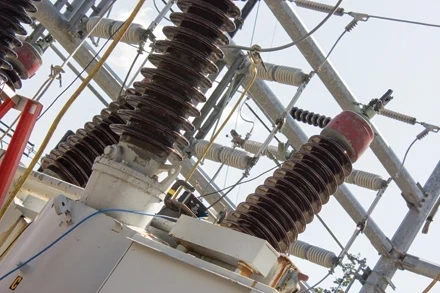

IR Inspection Windows for Electrical System Reliability

An Infrared Inspection Window is used to separate environments of differing pressures or temperatures while allowing light energy at a specified electromagnetic wavelength to pass between the two environments. They must meet the strength and environmental requirements for the type of equipment in which they are fitted, as well as be compatible with the infrared inspection equipment being used.

IR Inspection Windows enable the following:

- Collection of real-time, condition status data on critical electrical systems and components

- Mitigates the risk of injury or fatality during inspections because the window maintains an enclosed and guarded condition

- A comprehensive, safe, and intelligent protocol be designed and used for performing essential energized inspections on electrical equipment

What Specifications Must Be Considered When Choosing Infrared Inspection Windows?

IR windows allow infrared cameras to see and measure temperature of objects and connections inside energized electrical equipment with the covers and doors in place (maintaining a safe and guarded condition). IR Windows allow visual, Infrared, and Ultrasound inspections and they provide a safe and cost-effective way to conduct inspections on energized electrical equipment.

- Multi-technology Maintenance Inspection Windows: These windows go beyond just infrared inspection by adding ultrasound capability. In addition to allowing for thermal imaging, visual and UV inspections, ultrasound, and partial discharge inspections can be performed – all from a single window. This approach is cost-effective for the company overall as one type of window can accommodate multiple inspection modalities.

- Field of View (FOV)- takes into consideration the viewing angles and distance from the object of the camera and window working simultaneously. Are all the internal objects visible to the camera or is something blocking the camera’s view? The FOV calculation determines the size of inspection window needed for each piece of equipment. When specifying windows on new equipment, make sure to specify the targets you want to be able to see and put the responsibility for selecting appropriately sized windows onto the OEM’s design team.

Read full article in the Electrical Reliability Systems Special Edition 2022