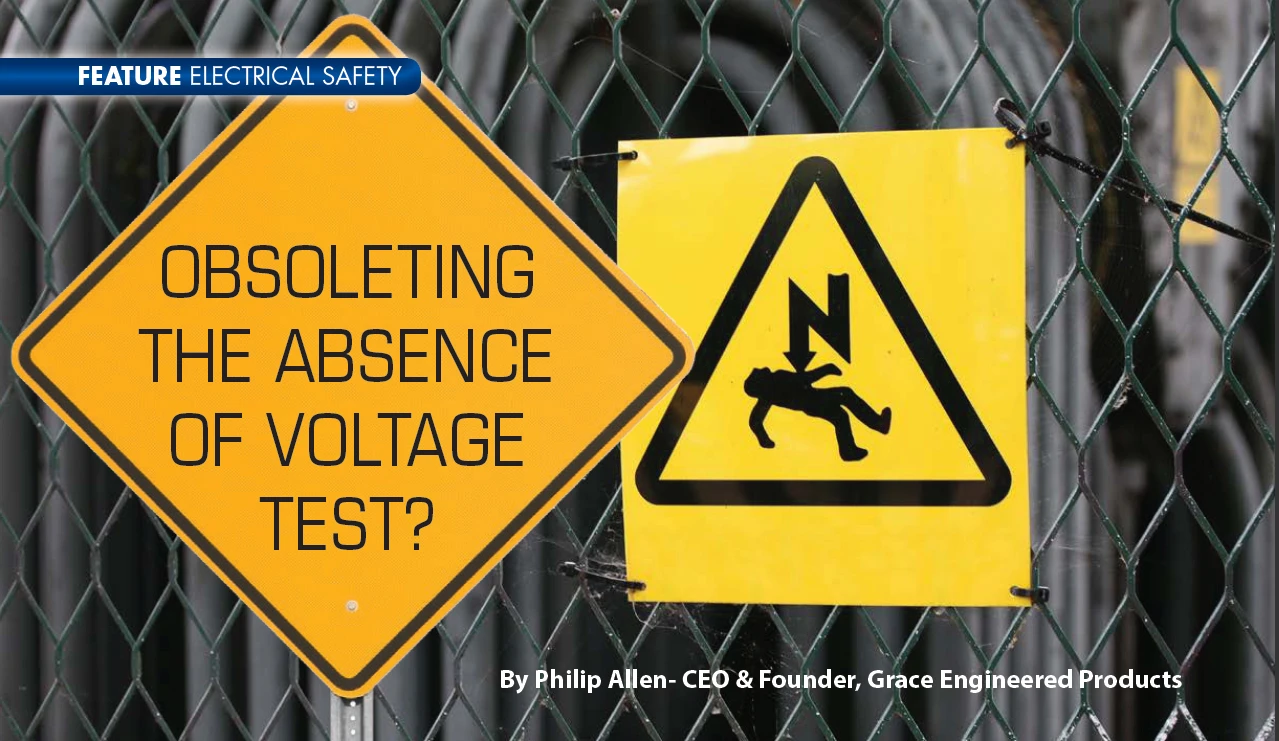

Obsoleting The Absence Of Voltage Test?

For more than a decade, thousands of users have deployed Permanent Electrical Safety Devices (PESDs) to reduce the risks in isolating electrical energy. This elegantly simple innovation increases the probability that workers are only exposed to ‘zero voltage’ when doing an absence of voltage test. The cumulative experience end users have amassed by using PESDs encouraged UL to create a new product specification for permanently mounted Absence of Voltage Testers (AVTs). Because UL acted, the 2018 edition of the NFPA 70E 120.5(N) also included an exception allowing AVTs to be another way to create an electrically safe work condition instead of a portable voltmeter.

But perhaps, the real accomplishment in the NFPA 70E 120.5(N) is that the foundational principles for permanent voltage test devices now exists in a consensus standard. Looming questions remain; will AVTs obsolete the portable voltmeter? Will electricians trust them? How will OSHA weigh in on the use of an AVT over the tried-and-true voltmeter test? No doubt, these issues will be settled over time. At least for now, guiding principles are in place to fuel innovation and determine the future for AVT product standards. The consensus standards processes, new product engineering innovations, better product certifications will result in AVTs that will stand up to the rigors of daily usage in the field by workers who depend upon them daily for their safety.

Without question, the highest risk task for qualified electrical workers is creating an electrically safe work condition. Today the minimum OSHA compliance for this task is essentially a qualified worker with a voltmeter in-hand donned in PPE doing a voltage test inside an electrical panel. Over the past decade, a deeper understanding of arc flash energy highlighted the risk of voltage exposure to health and safety managers. Since then, many Fortune 1000 companies mitigated this risk by installing hundreds of thousands of PESDs into electrical equipment as part of their safety programs as aids for isolating electrical energy during Lockout/Tagout (LOTO). Validated installation procedures for PESDs combined with LOTO procedures significantly reduces the likelihood that workers will be exposed to voltage when creating an electrically safe work condition.

Read the complete article here: http://online.electricity-today.com/winter-20172018/~12/