Exploring Online Dissolved Gas Analysis Monitoring for Transformer Insulating Fluids

As a philosophy and English major who has spent the last 20+ years working in the utility industry,

I often come across topics that challenge me because I don’t have a science or engineering background. This article is an exploration of the basics around online DGA monitors, to better understand the technology and the pros and cons associated with the different options.

Dissolved gas analysis (DGA) is the most widely-used test conducted on transformers while in operation in order to screen for incipient faults in the main tank. Essentially acting like a blood test for your transformer, DGA is traditionally carried out manually, with samples of insulating liquid extracted from the transformer and analyzed in a laboratory to determine the amount of gas in the liquid insulation. The results can reveal abnormal behaviour inside the transformer.

However, the use of online DGA transformer monitors is growing, and there are now many options available in the marketplace. While online monitors do not replace manual testing (because of concerns regarding their reliability and because of the need to test for fluid quality, furans, PCB levels, etc.), they can provide data far more often than lab sampling alone, as online DGA monitors can take readings at intervals as frequent as minutes to hours depending on the technology. There are two main categories of DGA monitors available in the market: single (or composite gas) monitors and multi-gas monitors.

Single or composite gas monitors primarily measure 1-3 gases and employ a number of fairly simple technologies:

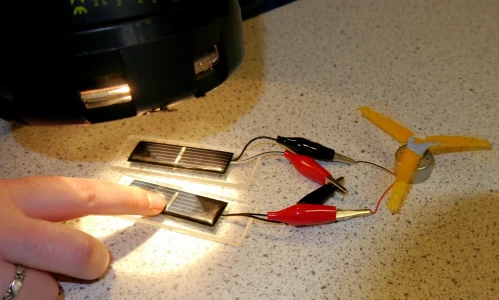

Solid state sensors have no moving parts and directly measure the gases in the liquid insulation. They can operate under extreme conditions, such as high or low temperatures, strong vibrations, or highly-corrosive environments. While they are reliable, robust, inexpensive and very low maintenance, the technology is limited to only a few select gases such as hydrogen. They also do not typically detect very low gas concentrations.

Thermal conductivity detectors are stable and quick to respond with a wide measurement range, but their readings can be distorted by other gases and the heating element can react with the gas it is measuring.

Fuel cells provide a composite gas measurement of several gases, primarily hydrogen and carbon monoxide, allowed to pass through a membrane. They are small in size and require periodic replacement.

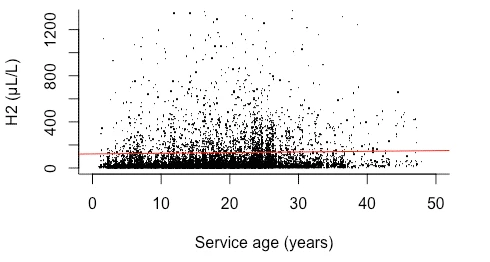

These monitors have the advantage of being lower cost than multi-gas monitoring devices. Since they only monitor one or a few gases, they don’t provide enough information to identify a fault type. However, their detection of hydrogen and/or composite gases allow them to function as an effective “event detector” or “smoke alarm” for new faults and include actual measured values. If an alarm is triggered, additional laboratory testing is recommended to provide the more detailed analysis needed to classify the potential fault.

Hydrogen is generated by thermal or electrical faults affecting the liquid insulation. Monitors that measure carbon oxide gases can detect thermal faults affecting the paper insulation. Monitoring these two parameters means you can get a quick idea of whether anything bad is happening inside your transformer.

Hydrogen monitors are relatively inexpensive, so they can be suitable for those with a lower budget, with a very large fleet of transformers, or for those who want to monitor small transformers. As well, because the initial detection of hydrogen is a key indicator that the transformer has started gassing, it is preferable to have the monitor on the transformer at time of installation; if it is put in place after the gassing has started, the detection of a new fault may be missed.