Hydrogen Monitoring in the Transformer Headspace Compared to Traditional In Oil Monitoring

The utilization of online dissolved gas analysis monitoring has proven to be one of the most effective predictors of overall transformer health and condition. A wide range of monitoring systems are available, offering multiple costs, features, and benefit combinations.

Hydrogen Monitoring

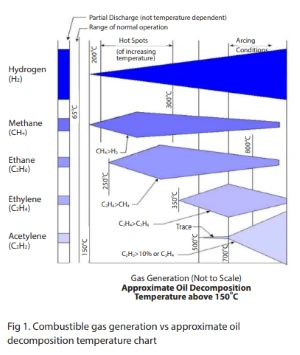

Single or key gas monitoring relies on the use of a sensor for the detection of hydrogen levels either dissolved in the oil or accumulated in the gas space of a transformer. While hydrogen monitoring alone does not provide enough detail to perform any advanced analytics, it is very useful in the early detection of incipient faults. This is due to the manner which hydrogen generates when compared to the other hot metal gases.

Hydrogen begins generating at 150°C and continues to generate directly as the fault temperatures increase. This unique property makes hydrogen the best single indicator of not only excessive thermal conditions, but also dielectric faults occurring within a transformer. In addition, hydrogen gas is also a key indicator of both arcing and partial discharge conditions.

Hydrogen’s Solubility In Oil

However, there are many factors which must be taken into consideration when implementing hydrogen monitoring for condition assessment of a transformer. Perhaps the most critical of these factors is hydrogen’s solubility in oil. Due to hydrogen’s low solubility in mineral oil, ppm values of dissolved hydrogen may be greatly affected by the design of the transformer, as transformers with nitrogen preservation systems will result in hydrogen quickly migrating across the gas oil partition, causing approximately a 20:1 ratio of gas in the headspace versus that which is dissolved in oil.

Read the full article in our Transformer Technologies Special Edition