Transformer Core Grounds

Transformer core grounds: a different path to maintaining insulation systems

BY JAMES WHITE, Shermco Industries, Inc.

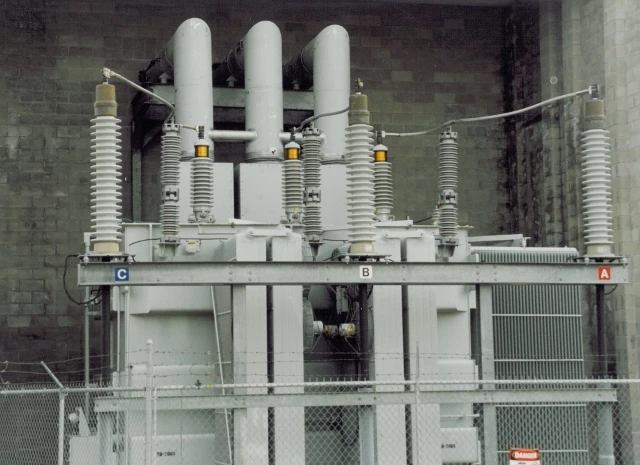

Power transformers are usually supplied with a ground from the core of the transformer to the tank (earth/ground). Smaller, dry-type transformers may not have this ground, but it is always used on larger transformers. Grounding a transformer’s core may not sound like a smart thing to do, but it is a very necessary part of the transformer’s insulation system.

Power transformer cores are constructed of sheets of grain-oriented silicone steel, designed to have a very low resistance to the flow of magnetic flux (reluctance). These sheets of silicone steel have a very thin coating of varnish or enamel on them so they are magnetically coupled, but electrically separate. The transformer’s windings are wound around the core, with the low-voltage winding wound against the core and the high-voltage winding wound over it. This arrangement reduces the dielectric stress between the low- and high-voltage windings and between windings and core. Transformers will be wound as core-form or shell form types.

Because of the construction of the transformer core/winding assembly, there can be high potentials induced into the core, causing partial discharges which will damage the transformer. The core ground diverts this voltage safely to ground. The core ground also provides a low-resistance path to ground if there is a short circuit between the winding and the core, allowing protective relaying to detect it. The core ground may be brought out to a separate, external bushing or it may be connected internally, with cost being the driving factor as to its location. As it is with most investments, you get what you pay for.