12 Tips to Protect Against Common Lineworker Safety Hazards

Lineworkers face numerous risks daily, from respiratory ailments to electrical hazards. These dangers can result in severe injuries, low blood pressure, bleeding, and vomiting. However, by adhering to established safety protocols, contractors and employers can significantly reduce the likelihood of accidents. Below are 12 practical tips to protect lineworkers from common safety hazards.

1. Identifying Job Hazards

The first step to mitigating risks is recognizing them. Conduct regular inspections of the worksite to identify potential hazards. Evaluate equipment and work conditions to detect safety threats that may be difficult to eliminate. Interview workers and managers to understand their concerns and observations. Use this feedback to create a detailed hazard map, marking both existing and potential hazards.

Involving workers in this process fosters a culture of safety and boosts morale. It’s crucial to maintain electrical installations, repair faulty appliances, and ensure the proper use of high-quality footwear. By addressing these concerns, employers create a safer working environment.

2. Using personal protective equipment

PPE is essential for protecting workers from injuries, infections, and other workplace hazards. Lineworkers should wear safety goggles, face shields, gas masks, and self-contained breathing apparatuses to guard against chemical splashes, burns, and respiratory diseases.

Ensure that all PPE complies with safety standards. Goggles and face shields should be free of cracks, and hard hats must be dent-free and stored away from high heat to maintain shell integrity. Workers should also wear high-visibility, heat-resistant overalls and gloves to protect against extreme temperatures and toxic substances.

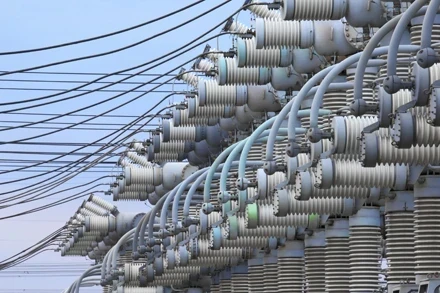

3. Properly using cover-up equipment

Cover-up equipment shields lineworkers from energized machines and electrical currents. Items like line hoses and conductor covers prevent accidental contact with live conductors, thereby reducing the risk of electric shocks and arc flash hazards.

To maximize protection, ensure that workers have access to appropriate cover-up equipment. Regularly inspect and maintain these tools to ensure they remain in optimal working condition.

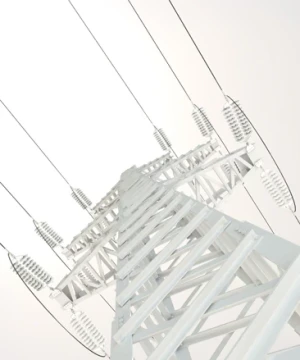

4. Protecting against currents in grounded systems

Grounded systems are often perceived as safe, but they can still pose risks due to electromagnetic fields. Under extreme conditions, these fields may create currents that endanger lineworkers.

To prevent such hazards, regularly inspect all equipment before use. Conduct safety training to educate workers about these hidden dangers and establish protocols for handling grounded systems safely.