Sales Order Automation for Electric Utilities

In today’s technology driven society, the pace of business is faster than ever. With access to new tools and innovations, electrical distributors are continuously expected to improve efficiency and customer service, delivering more with less and in increasingly rapid ordering cycles. Faced with this ever-growing demand, it has become vital that these distributors optimize their operations, enhancing the efficiency of business processes to remain competitive.

Yet it can often be difficult to narrow down and identify areas in need of improvement that will actually generate the necessary high return on investment (ROI). The important factor to remember is that future success in the distribution industry firmly hinges on the ability to embrace the unique requirements of each customer while processing orders rapidly and accurately. This makes identifying areas for improvement a lot easier as the key to achieving this balance is to eliminate error-prone manual order entry, automating the process to accelerate order-to-cash cycles.

Most electrical distributors already have dependable Enterprise Resource Planning (ERP) systems in place to help them automate repetitive administrative tasks, such as inventory control, accounting and shipment. Yet, many still process their customer orders by hand. This procedure entails a huge amount of manual entry from their customer service teams, compiling orders as they arrive and manually processing each one individually before re-entering it into the ERP system as a sales order. In addition to being a slow, labor-intensive task, it is a highly inefficient and expensive use of staff time, prone to continuous, embarrassing errors. Automation of the order-to-cash cycle would render this supplementary work redundant, eliminating manual entry and improving efficiency in a way that generates high ROI. In fact, not only does it reduce operational costs and liberate staff time to focus on customer service, but it also increases a company’s profitability. With faster order-to-cash cycles, electrical distributors can better manage their cash flow and make capital available to reinvest in their companies.

THE DIFFICULTY OF ELIMINATING MANUAL ORDER PROCESSING

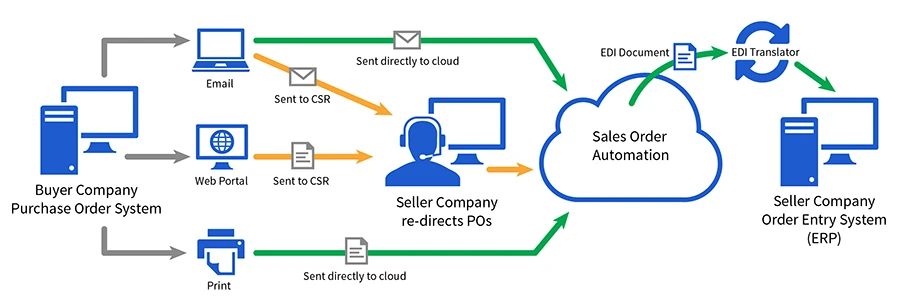

While the benefits of automating order-to-cash cycles are great in theory, until recently, in practice the ability to do so has not been readily available. In order to implement automation of this process, customer purchase orders have to arrive in a standard format to be automatically translated into a sales order in the electrical distributor’s ERP system. While there are solutions which offer this opportunity, such as Electronic Data Interchange (EDI), they require considerable time, money and a high level of collaboration with customers to execute. Both parties would need to have access to dedicated technical expertise and be able to devote substantial amounts of time and man-power to implement new software and business processes. Of course, once in place, their benefits are well worth the investment, improving data quality, reducing cost per transaction, eliminating manual order processing - liberating staff time - and creating shorter order-to-cash cycles.

Unfortunately, many customers have neither the technical resources nor the desire to help introduce this solution into their business communications. Each customer has their own distinctive internal processes and ways of doing business. Some use fax, others favor email and others still choose to mail their purchase orders in. With their own systems in place, they are, therefore reluctant, to duplicate effort, creating purchase orders for their own internal business processes and then entering the same order a second time in a shopping cart or web form for the electrical distributor. Thus, while EDI proves that automating order-to-cash cycles is the right step for high ROI optimization, the reality is that leveraging the investment in this solution is difficult without burdening the customer.

With the drawbacks of EDI, and hundreds of orders arriving daily for processing in different formats, what is needed is a means to bridge the gap between customer convenience and the supplier’s need to optimize and accelerate order-to cash cycles – a sales order automation solution.

BRIDGING THE AUTOMATION GAP

Sales order automation solutions can now fill the problematic gap between the electrical distributor’s increasing need for innovation to improve efficiency and each customer’s unique needs and convenience.

However, not all sales order automation solutions are created equal. It is vital that companies assess each solution thoroughly in order to select the one which best suits their requirements. For example, solutions which use traditional Optical Character Recognition (OCR) technology to estimate data are less accurate than non-OCR based ones. For example, characters such as a straight line may be misinterpreted by OCR as the number one, letter I, or the letter L. While small companies may have the capacity and man-power necessary to ensure the process works properly, larger organizations with greater order volumes will probably want to invest in superior, non-OCR technology.

Non-OCR solutions allow companies to treat email, fax and print orders like standard electronic documents, capturing the actual data from them with 100% accuracy and demanding a fraction of the time spent on manual order processing. Once captured, the data then flows into the company’s ERP system and is automatically routed to the appropriate channels with total visibility.

By implementing these solutions, error-prone manual entry is no longer necessary, eliminating its damaging effects on customer care and order-to-cash cycles. Customer service teams can then refocus their energy on other duties rather than dividing their time between providing assistance and entering sales orders into the electrical distributor’s internal system. Even better, these solutions can work in conjunction with an existing EDI investment or on their own, allowing companies to optimize and accelerate their sales order cycles accurately and without the need to inconvenience or change the way their customers do business.

Revere Electric Supply, a fourth generation electrical and automation distributor based out of Chicago, looked to accelerate order cycle time with sales order automation. With nine locations to manage across the Midwest, Revere serves numerous industries, including original equipment manufacturers, repair operations, systems integrators, contractors and government agencies. Beyond providing quality parts, they also focus on helping their customers create efficiencies, increase productivity, and maximize profitability.

With an ERP system already in place providing noticeable improvements to the efficiency of their inventory control, warehousing and reporting, the company was looking for further ways to eliminate bottlenecks for their business including sales order processing. Their large customer base meant that they received hundreds of orders to process daily in different formats. Some of their larger customers were willing and able to introduce EDI into their communications, while others were prepared to duplicate effort to enter their purchase orders into their own systems and then input them again in Revere Electric’s e-commerce web form. But most customers, especially those who sent large, frequent orders with part numbers already loaded into their own purchasing systems, preferred to place their orders in the traditional fashion via email, print and fax.

Each ordering method involved its own set of challenges but the notable issue arose from the consistent need to rely on manual order entry. Most of the orders arriving had to be manually processed and entered into Revere Electric’s ERP system by their customer service team, an expensive and wasteful use of their most valuable asset – their employees. With orders containing potentially hundreds of intricate part numbers, the process was not only predictably slow and impractical, but it also led to increased risk of human error. The inevitable mistakes cost Revere Electric significant time and money in rush orders and returns, putting pressure on their staff and risking their customer service reputation.

LAST LOOK

Sales order automation proved to be an effective solution for Revere Electric. Regardless of the format in which sales orders arrived, they were processed automatically with accuracy and without the need to change existing customer business practices. Not only did customers receive what they needed when they needed it, but they received it a lot faster. Revere Electric reported 95 percent time savings, with orders of all lengths and complexities processed in minutes rather than hours. This meant that their customer service teams were released from a large, repetitive portion of their duties. That extra time and energy could then be turned from manual order entry to more important tasks, such as providing extra care to customers with more complex and intensive orders. Ultimately, order-to-cash cycles were greatly improved, costly returns and rush orders were eliminated, customers received better service and staff themselves felt more motivated to do their jobs. Currently, Revere Electric's sales order automation solution processes over 4,000 order lines, exceeding $1.2 million in revenue each month.

Regardless of whether the customer purchase order arrives in email, online or EDI format, a sales order automation solution can help electrical distributors accelerate order-to-cash cycles. Once introduced, increasing demand can be met in a timely manner without changing the way customers do business. In fact, there is no need to even inform customers of changes to the sales order process so electrical distributors can process and ship orders more quickly and with guaranteed accuracy. Automation can provide companies with that competitive edge to handle higher volumes of orders without adding additional staff and move from customer order to payment more rapidly and efficiently than ever before.

Brent Halverson is President & CEO of ecmarket, cloud solutions developer of the patent-pending Conexiom sales order and invoice automation solution. Conexiom allows manufacturers and distributors to focus on serving customers and managing supplier relationships instead of entering data. For more information visit conexiom.com.